IECEx Certification Cost vs Long-Term Risk

A manufacturing director in Dammam once told me he saved $30,000 by skipping IECEx certification. Six months later, his company lost a SR 12 million Saudi Aramco contract because their equipment didn’t meet tender specifications. The “savings” evaporated in one rejected bid. This scenario repeats constantly across the Middle East—manufacturers viewing certification as an expense rather than risk mitigation investment.

Understanding IECEx certification costs requires looking beyond initial fees to the complete financial picture: what certification actually costs, what non-compliance risks financially, and how proper certification generates measurable returns. For manufacturers targeting UAE, Saudi Arabia, and broader GCC markets, this cost-benefit analysis isn’t theoretical—it’s the difference between sustainable growth and expensive market exclusion. Let’s break down the real numbers and examine why treating certification as insurance rather than expense changes everything.

Breakdown of Certification Costs

IECEx certification involves multiple cost components that vary based on equipment complexity, manufacturer location, and certification scope. Let’s examine actual numbers rather than vague estimates, because budgeting requires precision.

Initial certification fees from IECEx Certification Bodies (ExCBs) typically range $15,000-$50,000. Simple equipment like junction boxes or basic enclosures might fall toward the lower end—perhaps $15,000-$25,000. Complex electronic systems, control panels, or equipment requiring intricate intrinsic safety calculations push toward $40,000-$50,000 or higher. These fees cover design review, technical assessment, and certificate issuance.

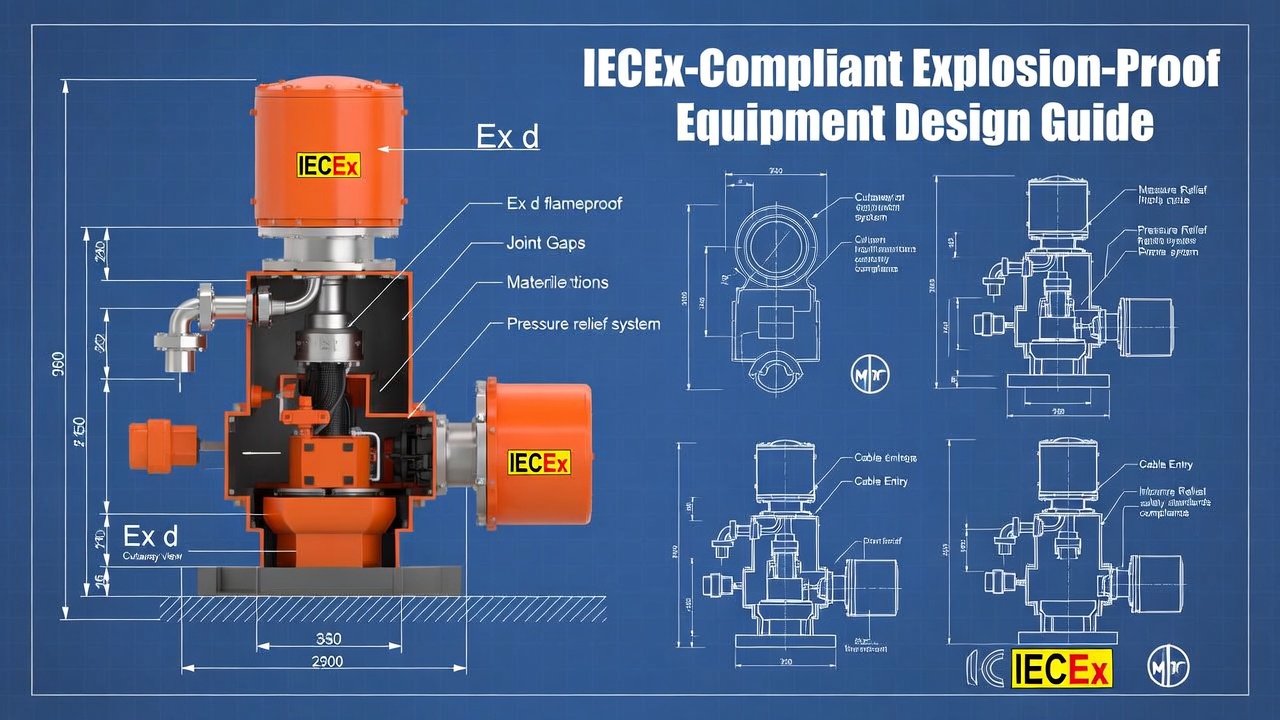

Testing costs represent a separate significant expense. Accredited laboratory testing for explosion-proof equipment runs $8,000-$25,000 depending on protection type and required tests. Ex d flameproof testing (actual explosion tests) costs more than Ex e increased safety testing due to specialized chamber requirements and safety protocols. If your equipment requires testing for multiple protection types or operates across different temperature classifications, multiply accordingly.

For manufacturers in UAE or Saudi Arabia, add regional cost factors. Travel expenses for auditors conducting factory assessments typically add $3,000-$6,000 per visit. If your technical documentation isn’t in English, translation services might add $2,000-$5,000. Some certification bodies charge premium rates for expedited assessment—if timeline matters, expect 20-30% cost increases for faster turnaround. Understanding the complete IECEx certification process helps anticipate these additional costs accurately.

The ExQA (Quality Assessment) certificate adds another layer. Initial ExQA assessment costs $8,000-$15,000, covering comprehensive factory audit, quality system review, and manufacturing process verification. This isn’t optional if you’re serious about serving major GCC projects—end users increasingly require both ExCB and ExQA certificates.

Don’t forget ongoing costs. Annual surveillance audits for ExQA maintenance run $3,000-$8,000 per year. Certificate renewals every five years require partial re-assessment, typically 30-50% of initial certification costs. If you modify your design or add product variants, expect modification assessment fees of $2,000-$10,000 depending on change scope.

Here’s a cost many manufacturers overlook: internal resource commitment. Your engineering team will spend 200-400 hours preparing documentation, coordinating with certification bodies, supporting testing, and implementing any required design modifications. At $75-$150 per hour for qualified engineers, that’s $15,000-$60,000 in internal labor. Professional IECEx certification training for your team ($2,000-$5,000) reduces this time by building expertise that prevents costly mistakes.

Consultants offer another option. Specialized IECEx consultants charge $10,000-$30,000 to prepare documentation, coordinate certification, and guide you through the process. For first-time certifications, this investment often pays for itself through avoided delays and mistakes. The choice depends on your internal expertise and timeline urgency.

Total realistic budget for comprehensive IECEx certification (ExCB + ExQA) for moderately complex equipment? Plan $45,000-$80,000 initially, plus $5,000-$10,000 annually for maintenance. That’s substantial, but context matters—compare this to alternative costs we’ll examine next.

Hidden Costs of Non-Compliance

The real cost conversation isn’t certification expense—it’s the financial impact of operating without certification in markets that demand it. These costs hide in lost opportunities, project rejections, and operational limitations that compound over time.

Contract rejection represents the most obvious cost. When your equipment gets rejected from a project due to certification gaps, you absorb multiple financial hits simultaneously. There’s the returned equipment cost—shipping, handling, restocking. There’s the penalty clauses many GCC contracts include for non-conforming equipment—often 5-10% of contract value. There’s the opportunity cost of that production capacity you allocated to equipment that generated zero revenue.

I documented a case where a motor manufacturer lost a $380,000 ADNOC contract due to missing IECEx certification. Beyond that immediate loss, the performance issue went into ADNOC’s vendor database, affecting their qualification for future opportunities. The downstream revenue impact over three years? Estimated at $2.1 million in lost bids they were excluded from due to vendor performance history. For detailed understanding of regional requirements, review information on IECEx certification in UAE markets.

Market access limitation creates chronic revenue suppression. Without IECEx certification, you simply can’t bid on major GCC oil and gas projects. Saudi Aramco, ADNOC, Qatar Energy, Kuwait Oil Company—their approved vendor programs require certification as baseline qualification. You’re not competing and losing; you’re not even in the game. For manufacturers whose target market includes these operators, non-certification doesn’t save costs—it eliminates revenue potential entirely.

Competitive disadvantage compounds over time. While you operate without certification, competitors who invested in it build relationships, secure repeat business, and establish preferred vendor status. They’re developing reference projects, expanding their approved vendor listings, and capturing market share. Meanwhile, you’re competing in lower-tier markets with compressed margins and limited growth potential. The revenue differential accumulates year after year.

There’s also the insurance and liability dimension. When incidents occur in hazardous areas—fires, explosions, injuries—investigators scrutinize equipment certification rigorously. Equipment without proper certification faces heightened liability exposure. Insurance claims might be denied or limited if non-compliant equipment contributed to incidents. Legal defense costs alone can exceed certification investment many times over, and that’s before potential judgments or settlements.

Consider delayed market entry costs. If you eventually pursue certification after years without it, you’ve lost market position during that delay. Competitors established customer relationships, optimized their products based on field experience, and built reputations. You’re entering late, lacking references, facing skeptical customers who wonder why you waited. First-mover advantages in industrial markets are substantial and difficult to overcome once lost.

Retrofit and redesign costs emerge when manufacturers attempt compliance after initial market entry. Equipment designed without certification in mind often requires substantial redesign to meet requirements. Those changes might affect tooling, purchased components, assembly processes, and testing procedures. Implementing changes post-production is exponentially more expensive than designing correctly initially. Some manufacturers discover their product architecture fundamentally can’t achieve certification without complete redesign—throwing away entire development investments. Understanding differences between IECEx vs ATEX certification helps avoid these costly redesign scenarios.

ROI of IECEx Certification

Return on investment for IECEx certification isn’t speculative—it’s measurable through contract wins, market access, premium pricing, and risk avoidance. Let’s quantify the returns using realistic scenarios.

Market access value: If certification enables bidding on projects you’d otherwise be excluded from, calculate the incremental revenue potential. For a manufacturer with $5 million annual revenue from hazardous area equipment, IECEx certification might unlock $2-3 million in additional addressable market from GCC projects. Even with 20% win rate, that’s $400,000-$600,000 additional revenue annually. Against $60,000 initial certification cost, you’re looking at payback within 3-4 months of first contract win.

Premium pricing capacity: Certified equipment commands 10-25% price premiums in many markets because customers value the reduced procurement risk, simplified approval processes, and liability protection certification provides. On $2 million annual sales, a 15% premium generates $300,000 additional gross profit. That premium often persists throughout product lifecycle, creating cumulative value far exceeding certification costs.

Contract retention and repeat business: Once you’re an approved vendor with certification, securing repeat business becomes dramatically easier. Project teams prefer working with proven suppliers who don’t create compliance headaches. I’ve observed manufacturers with proper certification capturing 60-70% repeat business rates versus 20-30% for those constantly fighting certification issues. The lifetime value of customer relationships built on certification compliance significantly outweighs initial investment.

Risk avoidance quantification: Calculate potential liability exposure, contract rejection costs, and penalty clause risks. If there’s even 10% probability of a $500,000 contract rejection over five years, the expected cost of that risk is $50,000—comparable to certification cost. Factor in liability exposure, insurance implications, and reputation damage, and risk mitigation value alone often justifies certification investment.

Time-to-market acceleration: Certified manufacturers submit bids with complete compliance documentation, accelerating approval processes by weeks or months compared to competitors who need technical exceptions, alternative compliance demonstrations, or design modifications during procurement. Faster approvals translate to earlier revenue recognition and improved cash flow—financial benefits that compound across multiple projects.

Consider a realistic scenario: Medium-sized manufacturer invests $65,000 in comprehensive IECEx certification. Within 18 months, they secure three contracts totaling $1.8 million that required certification as bid qualification. They capture 18% price premium on certified products worth $300,000 annually. They avoid one $200,000 contract rejection that would have occurred without certification. Total quantifiable benefit in first two years: approximately $2.3 million against $65,000 investment. That’s 35:1 ROI—extraordinary by any standard.

Tips for Budgeting Certification

Smart budgeting for IECEx certification involves strategic planning, phased investment, and leveraging resources efficiently. Here’s how experienced manufacturers approach it.

Phase Your Certification

You don’t need to certify your entire product line simultaneously. Start with highest-volume products or those targeting specific high-value opportunities. Secure initial certification, generate revenue from certified products, then fund additional certifications from that cash flow. This phased approach spreads costs over time while generating returns that fund subsequent investment.

Leverage Dual Certification Economies

If you’re pursuing both IECEx and ATEX, many certification bodies offer combined assessment packages reducing total cost by 20-30%. The testing overlaps significantly—explosion tests, temperature assessments, ingress protection verification serve both certifications. Documentation preparation addresses both simultaneously with minor modifications. Bundle certifications when it makes strategic sense. Resources comparing IECEx vs CompEx in UAE, Saudi Arabia, and Qatar help determine optimal certification combinations.

Use Pre-Certified Components

Component manufacturers increasingly offer IECEx-evaluated products with published safety parameters. Using pre-certified cable glands, terminal blocks, enclosures, and electrical components reduces your assessment complexity and costs. The incremental cost of certified components versus standard alternatives is minimal compared to system certification time savings they enable.

Invest in Documentation Systems

Proper documentation management—CAD systems, document control, version management—reduces certification preparation time dramatically. The $5,000-$10,000 invested in documentation infrastructure saves 50-100 engineering hours per certification cycle. For manufacturers pursuing multiple certifications or product variants, this infrastructure pays for itself quickly.

Build Internal Expertise

Training your engineering team in IECEx requirements through professional programs costs $2,000-$5,000 but reduces ongoing consultant dependency. Teams with certification expertise prepare better documentation, make fewer design mistakes requiring correction, and manage certification maintenance efficiently. This capability becomes organizational asset valuable across all future products. Understanding comprehensive IECEx zones and protection concepts builds this foundational expertise.

Schedule Strategically

Certification body workloads fluctuate seasonally. Scheduling assessments during slower periods (often Q1-Q2) sometimes enables negotiating better rates or faster turnarounds. Testing laboratories similarly have capacity variations. Strategic scheduling can save 10-15% on costs while improving timeline.

Plan for Contingencies

Budget 15-20% contingency for unexpected costs—design modifications discovered during assessment, additional testing if initial samples fail, expedited shipping of replacement test samples. Manufacturers who budget contingencies avoid desperate scrambles when issues emerge. Those who budget exactly to estimates face painful choices when inevitable complications arise.

Frequently Asked Questions

Is IECEx expensive for small manufacturers?

IECEx certification costs $45,000-$80,000 initially, which represents significant investment for small manufacturers. However, the cost should be evaluated against market access and revenue potential, not absolute dollars. Small manufacturers often pursue certification for single high-volume product first, generating returns that fund subsequent certifications, making the investment manageable through phased approach.

Can cost vary by region (UAE/KSA)?

Yes, certification costs vary by region due to travel expenses for auditors, potential translation requirements, and local certification body presence. UAE and KSA manufacturers typically pay 15-25% more than European manufacturers due to auditor travel costs and developing regional infrastructure, though this gap is narrowing as more ExCBs establish Middle Eastern operations.

What’s the biggest hidden cost of certification?

Internal engineering time represents the largest hidden cost—typically 200-400 hours preparing documentation, coordinating assessments, and supporting testing. At $75-$150/hour for qualified engineers, this adds $15,000-$60,000 to visible certification fees. Proper planning and training reduces these hours significantly, making this controllable cost with right preparation.

How long before certification investment pays back?

Most manufacturers see payback within 6-18 months through contract wins requiring certification. A single $500,000 contract with 20% margin generates $100,000 gross profit, covering typical $65,000 certification investment in one project. Manufacturers targeting high-value GCC projects often achieve payback in first contract win.

Should we certify before having confirmed orders?

Yes—certification takes 6-12 months, and most major projects require certification at bid submission, not after contract award. Waiting for confirmed orders means missing tender opportunities during certification process. Strategic manufacturers certify based on addressable market analysis rather than confirmed orders, positioning themselves to capture opportunities when they emerge.

Conclusion

IECEx certification costs are substantial but predictable—$45,000-$80,000 initially with $5,000-$10,000 annual maintenance represents realistic budget planning. The hidden costs of non-compliance—rejected contracts, market exclusion, liability exposure, competitive disadvantage—dwarf these amounts through cumulative impact over time. Manufacturers who view certification as risk mitigation investment rather than regulatory expense make fundamentally different decisions that protect long-term profitability and market position.

For manufacturers targeting Middle Eastern markets, the ROI calculation is straightforward: certification enables access to multi-million dollar projects that explicitly require it, commands premium pricing that persists across product lifecycle, and avoids rejection costs that can exceed certification investment in single incidents. Budget strategically, phase investments intelligently, and measure returns through expanded market access rather than avoided costs alone. Your certification investment today determines which opportunities you can pursue tomorrow.